Porsche’s New Six-Stroke Engine Explained

Porsche has apparently been working on a six-stroke engine and even filed a patent with the United States Patent and Trademark Office (USPTO) along with the Technical University of Cluj-Napoca. The motor is said to offer enhanced efficiency and power, along with cleaner combustion. However, it’s fairly common for the industry to promise the moon after announcing the revival of odd-ball technologies from the past or some totally novel powertrain.

Let’s not forget that hydrogen power and battery electric vehicles were both promised as global game changers, and both ended up struggling to supplant the internal combustion engine. While hydrogen development seems to have stagnated, strides made with EVs have proven that it’s certainly possible for novel technologies to catch on. All-electric vehicles still haven’t reached a point where they’re ready to supplant combustion models. But there are certainly applications where they’ve managed to thrive.

Porsche seems to think that it can continue the march of progress with the six-stroke engine. Which it described as an altered version of the traditional four-stroke engine which adds two additional strokes.

“This alteration allows for a second compression and power phase, effectively doubling the combustion events within a single cycle,” stated the automaker. “Think of it as a two-times-three-stroke system, where each piston compresses the fuel/air mixture twice, resulting in two distinct power strokes.”

For those needing a refresher on how engines work, the stroke represents the movement of a piston within the cylinder while a combustion engine is in operation.

On a four-stroke motor — like the one that’s situated beneath the hood of your daily driver — there is an intake, compression, power, and exhaust stroke. This means that the piston makes two complete passes inside the cylinder to complete a single operational cycle. Two-stroke engines only need a single revolution to accomplish the same task. But they’re not as popular as they used to be due to emissions concerns and are mainly limited to smaller applications (e.g. outboard motors, chainsaws, lawnmowers, mopeds) these days. Although, they do still see routine use on the massive diesel engines used for large container ships.

While there are actually several different designs for six-stroke engines, some of which are nearly as old as the automobile itself, they never took off due to the relative increase in mechanical complexity. Despite often being more efficient, via the addition of an additional power and exhaust stroke vs a four-stroke application, many were prone to overeating and typically needed elaborate thermal management.

Most early designs required water injection, and sometimes even leveraged excess steam to aid with propulsion, which meant adding an extra tank specifically for that purpose. But the water needed to be distilled to avoid corrosion and premature detonation. Running out of water also typically resulted in the motors overheating almost immediately. Combine that with novel cam or crank designs and six-stokes ended up being an extremely hard sell.

They were just too complicated. But modern motors are getting any simpler, to the chagrin of at-home mechanics everywhere. So we suppose there is an outside chance of something like this eventually coming to market. At a minimum, Porsche wants people to see it as thinking outside the box and existing on the cutting edge of technology — even if the original six-stroke motor is over 100-years old.

From Porsche:

One of the most compelling advantages of this design is its potential to significantly enhance both power and efficiency. With power generated every three strokes instead of the traditional four, the engine can deliver more consistent power output. Additionally, the second compression phase helps to “scavenge” gases [sic] from the first combustion, leading to cleaner emissions and improved thermal efficiency. Early estimates suggest that this six-stroke engine could achieve thermal efficiencies of up to 50 [percent], compared to the average 30 [percent] for four-stroke engines.

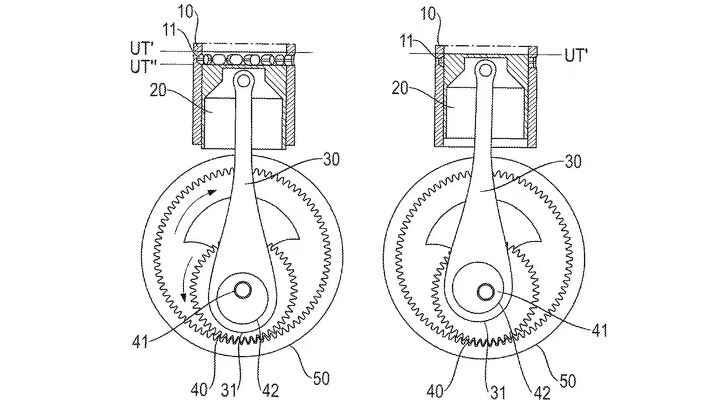

The engine achieves its unique cycle through a sophisticated crank mechanism that spins around a planetary gear while also rotating itself. This setup allows for two top-dead-center and two bottom-dead-center positions within the rotational cycle, thereby varying the piston stroke and compression across these positions. This contrasts sharply with the fixed-crank four-stroke engines, where the compression and stroke lengths remain constant.

With variable stroke lengths, Porsche can have a secondary bottom-dead-center that brings the piston below a series of ports in the cylinder wall that brings in more air and sends exhaust gasses to back up for a secondary compression and power stroke. The rest of the time, the cylinder wouldn’t drop low enough to utilize the “scavenge” ports and would function like a normal four-stroke engine. This is accomplished by the aforementioned ports inside the cylinder wall, along with a planetary and ring gear combination where the former has an offset attached to the crank that allows the piston rod to have those variable stroke lengths.

There is likewise a worm gear that coincides with the outer edge of the ring gear to help with variable compression ratios. But I’m admittedly not sure how that works since the ring would presumably need to rotate the ring gear while the motor was running. We’ve effectively exhausted my mechanical knowledge and what I was able to piece together from the patent drawings and the German brand’s rather brief explanation.

Some have alleged Porsche’s system vaguely reminiscent of forced induction, which attempts to leverage exhaust gasses to drive more air into an engine, in what it’s trying to accomplish. But the six-stroke engine actually attempts to burn up the excess exhaust inside the cylinder, rather than focusing entirely on using exhaust pressure to force in more clean air. While numerous six-stroke designs vary quite a bit in terms of how they operate, they do all share a common feature in that they try to take advantage of excess energy. Older versions attempted to use that heat to create steam pressure, whereas Porsche’s design is trying to recirculate un-burnt exhaust gasses so they might be converted into an extra power stroke.

While the feasibility of this system is unknown, the concept is certainly very interesting and would presumably help combustion engines adhere to the stringent, bordering on ridiculous, emissions rules being advanced by Western governments. It also functions on existing mechanical technologies, suggesting that it might be feasible if the manufacturer sorts out the necessary engineering to make it reliable.

Additional benefits would include the ability for a six-stroke engine to make more power than an identically sized four-stroke equivalent. However, were the industry to produce an exceptionally efficient four-stroke engine, the six-stroke loses some of its value proposition as there needs to be excess energy for it to recover in the first place. The only other concern would be engine balance as the offset gear could create additional vibration.

[Images: Porsche; USPTO]

Become a TTAC insider. Get the latest news, features, TTAC takes, and everything else that gets to the truth about cars first by subscribing to our newsletter.

Source: The Truth About Cars

Recent Posts

Ain’t No God Like God of War

From the original game to 2022's Ragnarok, God of War has shown time and again…

Apple’s M4 Mac mini plunges to $499, lowest price ever

Apple's latest M4 Mac mini is back down to Black Friday pricing, with the standard…

Analyst apologises for mistakenly claiming Final Fantasy 16 sold 3.5m copies

An analyst who claimed Final Fantasy 16 had sold 3.5 million copies has apologised, insisting…

‘Free Speech’ Platfrom X Suspends Opposition Party Accounts in Turkey

The bans follow demonstrations protesting the arrest of Erdoğan's main political rival.

‘MagicMiles’ travel itinerary app now lets users add transportation and lodging

I wrote last year about MagicMiles, a new app that helps users create entire travel…

GLENN DANZIG Has No Plans To Record An Album Anytime Soon: “I Really Don’t Have That Much To Say Musically”

"Maybe I'll do like an EP or something." The post GLENN DANZIG Has No Plans…