Renault Emblème concept shown at the Paris motor show is our first look at the next-gen EVs

Renault’s next EVs aim to slash battery costs by 50%, reduce charge stops to 15 minutes and achieve 5.2mpkWh

Renault will introduce a new generation of electric cars from 2028, promising such drastic improvements in efficiency, charging, sustainability and functionality that they will effectively “catch up two generations in one”.

One year on from its foundation, the Renault Group’s Ampere EV division is well advanced with development on the cars that will take Renault into the next decade, outlining plans to slash battery costs by 50% in the next three years, boost rolling efficiency to 5.2mpkWh and cut charging times to as little as 15 minutes.

The technological developments will be accompanied by a whole new approach to exterior and interior design.

The new Renault Emblème concept, revealed at the Paris motor show last month, gives strong clues as to what to expect from these upcoming EVs, with sleek, aerodynamically optimised bodywork, a futuristic minimalist interior and a radical powertrain that uniquely combines a hydrogen fuel cell with a battery-electric powertrain.

Renault CEO Luca de Meo went as far as to strongly hint that a subtly evolved evolution of the Emblème will be among the first of these cars to arrive, saying: “Maybe you think it is just a concept or a vision, but if you know me a little, you know that whenever I put something on a stage, I tend to do it in the end.”

Notably, Renault’s last three high-profile concepts – the 4, 5 and Scenic EVs – have all made production relatively unaltered.

Notably, de Meo suggested that the production version of the Emblème will ride on a “next-generation, revolutionary C-segment platform”, suggesting it will be technically unrelated to the Ampr platform-based 4, 5, Mégane and Scenic on sale today.

Continuing to invest heavily in Renault’s upcoming EVs is important, he said – even amid slowing growth in European EV uptake – because “EV is the future”, “no matter the short-term bumps and hurdles”.

“People are expressing concerns about the EV market plateauing,” de Meo added, “and don’t count on me to say that everything is fine: there are obviously huge challenges, and I think Europe must fix them urgently. But I also think it’s important that we put the focus back on the big future. And I would say from a long-term perspective, in fact, EV is the future, or at least it’s a very big part of the future.”

The EV market, he said, “is where growth is going to happen for the automotive industry in Europe”, while “the rest of the market will be flat or potentially declining” – justifying the decision to spin off Ampere from Renault a year ago.

Already, de Meo said, there is “scientifically no doubt” that an EV has a lower carbon footprint than an ICE alternative from cradle to grave, and Ampere’s development efforts mean Renault’s EVs will have a 70% smaller carbon footprint than their ICE counterparts by 2030.

Furthermore, he said that EVs are already cheaper than ICE cars from a total cost of ownership perspective and suggested that work to increase battery energy density, reduce production costs and make cars more efficient overall will help to further widen that disparity.

New battery tech

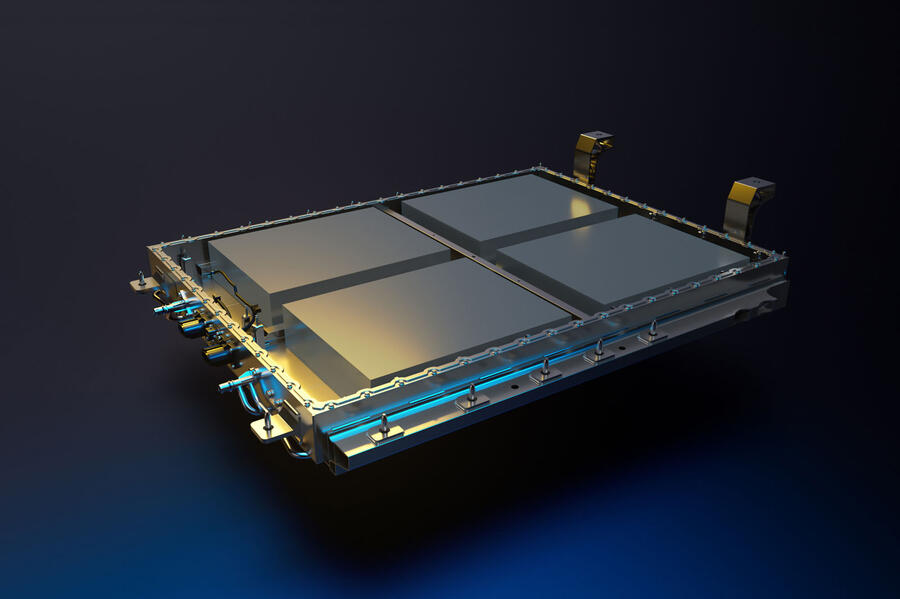

Among the most significant technical developments for Renault’s new-generation EVs will be the introduction of much more energy-dense battery packs, which it said will combine “the energy density of nickel-manganese-cobalt [NMC chemistry], the cost and safety of lithium-iron-phosphate [LFP chemistry] and less than 15-minute charges”.

Chemistry currently accounts for 60-75% of a battery’s cost, Renault said, which is the main factor in their price premium compared with ICE alternatives and the key incentive to invest in new types of cell that can reduce the cost to consumer.

From 2026, Renault will swap its mainstream EV batteries from NMC to LFP, which it says will reduce costs by 20% while having no impact on range.

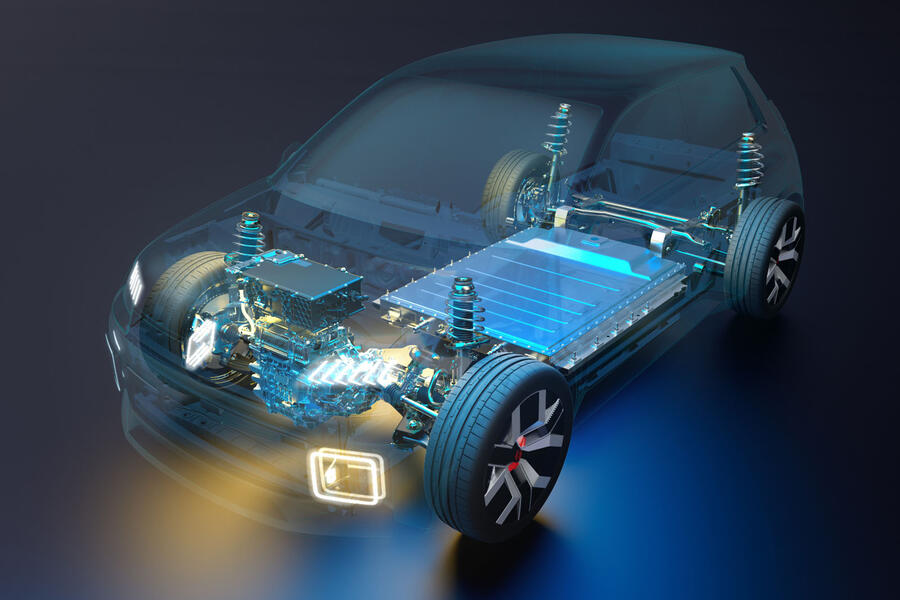

Ampere has worked with Renault’s EV platform developers to design a new cell-to-pack battery arrangement to compensate for the inherent reduced efficiency of LFP compared with NMC, so the cost reduction won’t be accompanied by any drop in energy output.

The company will boost that cost reduction to 50% (compared with today) by 2028, with the introduction of a new chemistry that combines a cobalt-free cathode with a silicon anode, which it says gives the energy density of NMC at the cost – and with the safety credentials – of LFP. An added benefit, it said, is that this chemistry allows for much quicker (15-minute) charging times.

Then, within the next decade, Ampere will look to double the energy density of its NMC packs by replacing the silicon anode with a lithium metal alternative – a composition that it refers to as the “building block” for solid state technology, which Renault plans to have in a production car within the next decade.

Alliance partner Nissan notably has confirmed plans to sell a solid-state EV from 2028, but when pressed for details about whether Renault could match that timeline, Ampere’s head of cell chemistry development, Mohamed Taggougui, would only say that the company was “talking to” its Japanese counterparts.

Renault’s engineers highlighted that 25-40% of the cost of a battery pertains to integration costs – by which they mean the casing and the way it’s mounted into the chassis – and halving that cost by 2028 is also key to Ampere’s plans.

Crucial developments here include the adoption of a new cell-to-pack battery design that maximises usable capacity, and work is in progress to adopt a cell-to-chassis arrangement in upcoming EVs, further increasing efficiency.

Cutting carbon footprint

At the heart of Renault’s electrification strategy is a push to dramatically reduce the carbon footprint of both its cars and its global operations.

That ambition is symbolised by the Emblème concept, which is projected to have a total lifecycle (15 years or 200,000km) carbon footprint of just five tonnes, compared with the circa-50 tonnes emitted by a petrol-engined, current-generation Captur.

Making the Captur electric would only solve “half this problem”, claimed sustainability boss Cléa Martinet, because of the impact of sourcing battery materials and the huge array of other components used throughout the car.

Martinet said that achieving net-zero in vehicle production is contingent on sourcing low-carbon energy, optimising the efficiency of battery factories and procuring battery materials with as small an impact as possible – all goals that Renault is attaching to the roll-out of its next-generation EVs.

Using recycled aluminium for battery casings and making steel bodywork panels – “one of the most resistant and demanding components of the car” – by combining iron ore with hydrogen in an electric furnace will also be crucial steps towards achieving that goal.

Asked by Autocar how Ampere will work to lower the carbon footprint of its wider supply network, Martinet said: “That’s part of our logistics decarbonisation strategy. We have an objective to reduce it by 20% by 2030.

“What’s really crucial here is that 75% of our tier-one suppliers are located in a 300km radius, because this is an automotive industry neurologic centre we’re in at the moment,” referring to the region around Renault’s ElectriCity EV production hub in northern France.

“It’s helpful for an EV car maker to have this very strong localisation in Europe,” she said, adding that it will be especially helpful when the EU’s new carbon border adjustment mechanism – which taxes the import of several key car-building materials – comes into effect.

Source: Autocar RSS Feed